Have any questions?

+44 1234 567 890

Powerful pumps for industrial use: The KIP 150 industrial pump from KLEIN is ideal for pumping thick materials. The double-piston pump with S-tube can deliver a maximum flow rate of 40 m3/h.

Year of construction: 2021

Available as: Electric / Sledge / Shotcrete

Year of construction: 2021

Available as: Diesel / Trailer

Year of construction: 2021

Available as: Diesel / Crawler

The KIP 180 industrial pump is characterized by its compact design and low maintenance requirements. This machine is ideal for tunnel construction. It is also available as a special micro version which is ideal for use in micro tunnel construction.

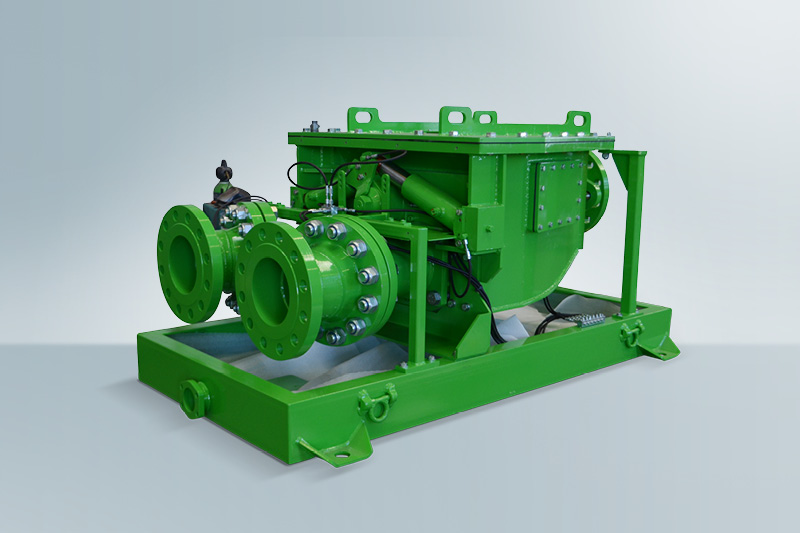

The hydraulic poppet valve pumps from Klein are designed for pumping highly viscous, viscous materials and substances with small particle sizes. The pumps are characterized by extremely low wear and high reliability.

The shotcrete manipulator is ideal for masonry renovation on bridges, tunnel driving, excavation support and slope sealing.

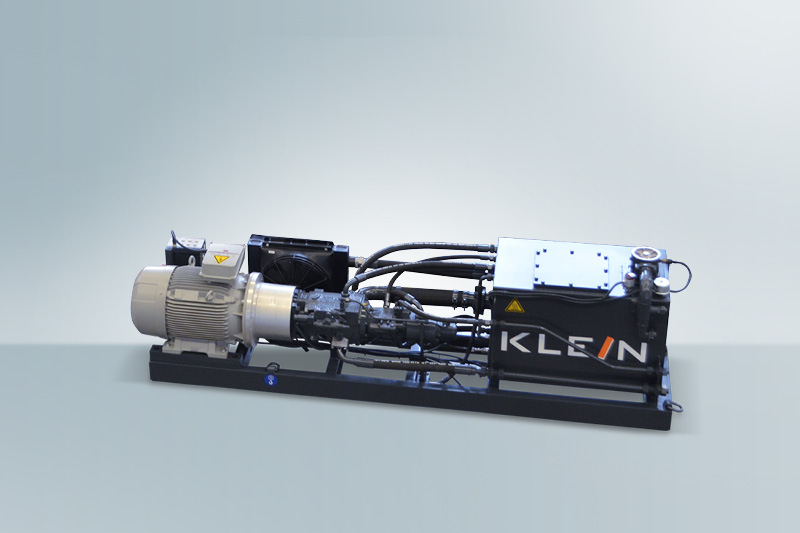

High thrust with emphasis: The powerful hydraulic power units from Klein always provide a powerful drive for slurry pumps. In addition to various standard versions, we can also provide you with hydraulic power units that are individually adapted to your requirements.

The pumps in this series are suitable for tunnel construction as well as for industrial or sewage sludge applications (special materials) with flow rates of up to 210 m3/h. The double-piston pump with S-tube is a low-noise high-pressure transport solution for your system thanks to the diverter valves.

Compact and reliable: The stationary concrete pumps in the 150 series from Klein have everything you need for concrete work in small and medium-sized areas. The concrete pump provides optimum service for smaller concrete jobs.

The shotcrete pumps in the 150 series are also characterized by their compact design and high reliability. The trailer pumps are available with a crawler chassis or with a carriage base.

Highly mobile thanks to a strong crawler or tracked chassis: The tracked concrete pumps in the 150 series are ideal for transporting smaller delivery volumes and are designed for use with drilling rigs for the construction of small and medium-sized bored piles.

With the compact 150 series trailer concrete pump from Klein, you can reliably transport pumpable materials even over long distances. The pump has a double piston and is available with an electric motor or diesel engine.

The series if you need a reliable all-rounder for demanding pump applications: Thanks to their extremely robust design, the stationary concrete pumps in the 180 series are well up to any challenge, large or small.

Very robust and mobile: The tracked concrete pumps in the 180 series have a high-quality finish and are always mobile, even on difficult ground, thanks to a tracked chassis - ideal for use in the construction of bored piles.

Extremely robust and powerful pump. Reliably pumps concrete and other pumpable media over long distances. Ideal for bored pile work in civil engineering and building construction.

Robust, compact, for high delivery rates. The pumps in the 180 series always deliver a strong performance in shotcrete applications - designed as a trailer pump, available with a choice of crawler or carriage base.

Our dry material mixing system sets new standards when it comes to reliable and smooth operation. Thanks to the new 4-dimensional mixing principle, this system achieves the optimum mixing effect.

The cost-saving nozzle reduces the delivery pressure of your pump and at the same time protects your construction machine.

In order to provide effective noise protection for a wide variety of machines, the sound enclosure can be adapted precisely to a wide range of requirements and needs.

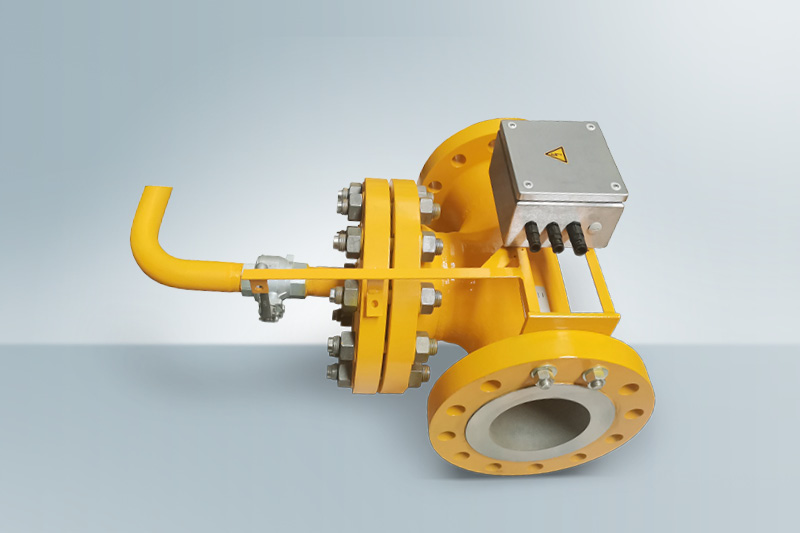

Maximum flexibility can be achieved with the S-pipe diverter. Thanks to the "2-way delivery valve", the direction in which the material is to be pumped can be decided on site as required.

The special machine uses a type of sieve to separate the pieces of material, which is available in various sizes.

The cleaning or inspection device is used for regular prophylactic pipe cleaning.

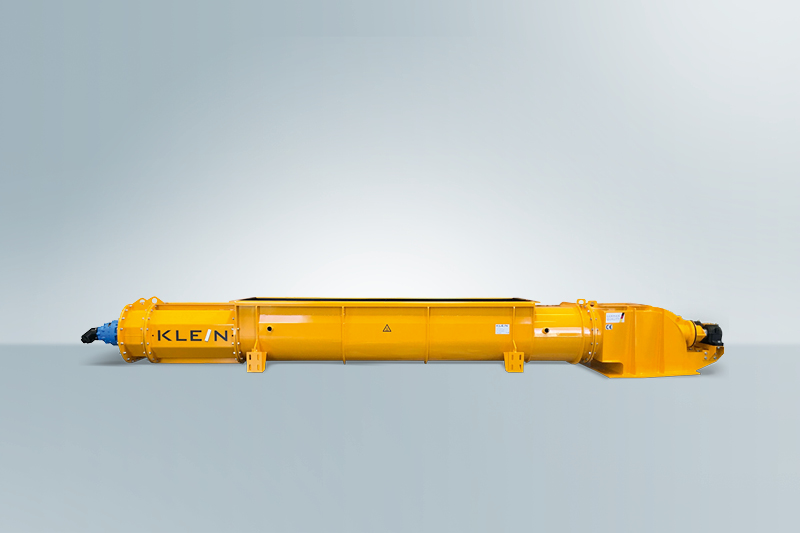

The pre-pressing device or screw conveyor makes it easy to transport solid, earth-moist and visually almost dry materials. The screw conveyors from KLEIN have been specially developed to be able to feed additional heat (up to 450 kW) into biomass.

The traversing device makes it much easier to move the machines for maintenance work.

Durable and robust: The double-piston trailer pumps in the 180 series withstand the most difficult requirements and reliably transport concrete and other pumpable materials over very long distances.

Our stationary pump power machines: The stationary concrete pumps in the 220 series always deliver a powerful performance. They also effortlessly and reliably transport large quantities of liquid materials over long distances.

Trimmed for performance: The chain concrete pumps in the 220 series are pure powerhouses when it comes to transporting large quantities of pumpable material. The powerful twin-piston pump reliably provides a good thrust.

Extremely robust and powerful pump. Both the electric and diesel versions can be mounted on a tracked chassis, skid or trailer.

The Klein 220 series trailer concrete pumps: our strong performers. With up to 171 m³/h, these twin-piston pumps transport concrete and other viscous materials reliably and efficiently, even over long distances.

Quality "Made in Germany

High quality materials for highest demands

German workmanship meets years of experience in mechanical engineering: KLEIN pumps are made exclusively in Germany from high-quality materials and components. For more than 25 years, the conception, design and construction of the machines have been carried out exclusively in our family-run mechanical engineering company in Jettingen-Scheppach.

The result: high-performance, trouble-free and robust equipment that has a long service life and guarantees companies a high level of investment security. Rely on premium quality "Made in Germany" in the field of pump conveying technology. And benefit from the high reliability and operational strength of our machines in the long term.

Always there for you personally

Do you have questions about our product range? Would you like more information about a specific type of machine? You can reach us during our opening hours by phone or mail!